Nashville Wire Group has been in the business of producing stocking carts for decades so we have a clear understanding of fit and function. But when the Display division was given the opportunity to develop a product for off-shore production, we immediately saw an opportunity to innovate our customers’ supply chain.

By developing a footprint and format that was supply chain friendly, our goal was to streamline the movement of product from origin to on-shelf by reducing the total number of touchpoints and delivering measurable savings to our retail customers.

Using the supply chain map as our starting point, here is how we challenged our development team to deliver innovation:

- Consider a solution that effectively circulates through the supply chain by optimizing every inch of space in all distribution channels.

- Robust, pre-assembled construction, but nestable for efficient shipping without

- compromising functionality or structural integrity.

- Challenging target cost to ensure our innovative solution was delivering added value at a competitive price position.

Working in collaboration with a major retailer, we established the most commonly used product container dimensions to help define our shelf area and spacing.

We then calculated our desired footprint based on maximizing floor space in 53’ truck when cart is fully loaded. And similarly, when empty carts are returned to depot, there was no wasted space on the truck floor.

Our goal was to provide a system that transported products from the central depot to the in-store shelf with no unnecessary handling in-between.

- Initial samples were produced and tested at our off-shore facility prior to finalizing production specifications.

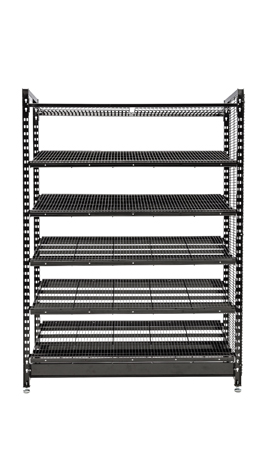

- Our innovative solution enables ease of maneuverability in confined spaces like narrow aisle and busy stock-rooms.

- Our folding, nesting solution maximizes container efficiency for reduced ocean freight and optimizes truck loading to deliver the most effective supply chain outcome.

BACKROOM GALLERY